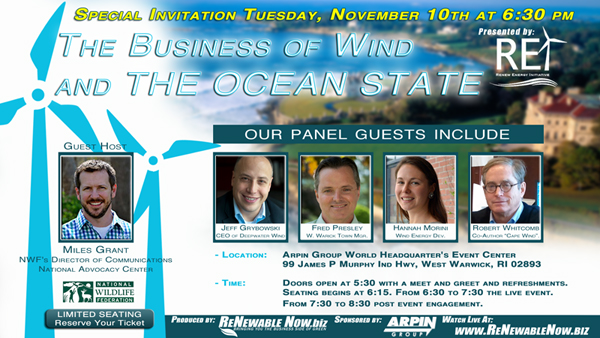

As you know we'll be doing a wind special on Nov 10. Certainly, we'll need to look at construction and the environmental risk wind can present. As with any project, shoddy workmanship--if proven here, as an example--will derail all progress.

We hope this nothing more than typical bumps in the construction of a multi-million dollar site, and all inspections will ultimately pass scrutiny, and clean energy starts to pour into RI through Block Island.

Concerns Over Quality of Wind Farm’s Construction

Welding questions join list of troubles compiled by CRMC

This month, attention shifted to the quality of construction — specifically welding procedures and construction practices by the builder, Weeks Marine of Cranford, N.J.

The list of problems includes broken testing equipment, unused moisture-extraction ovens and a lack of documentation. The problems were reported by ABS Group, a consultant hired by Deepwater Wind to monitor construction of the five-turbine wind farm.

“Every one of those issues to me is a major issue,” said Donald Gomez during the Sept 22 meeting of the Coastal Resources Management Council (CRMC), the state agency overseeing most aspects of the project. “You don’t work that way.”

Other CRMC members described the irregular practices as “very concerning.” Several were agitated by the prospect of unverified welding, unused and broken welding equipment, and faulty quality-control devices.

Some welding isn’t being documented nor is it sanded properly, according to Houston-based ABS. However, final inspections of the welds performed by Weeks awarded flawless scores. The grading was referred to as “implausibly 100 percent perfect” by CRMC council member Tony Affigne.

CRMC vice chairman Paul Lemont demanded better oversight from ABS.

“We don’t want to be caught short-handed here, because we’re on the hook and if something goes wrong they (the public) are going to look to us, and if you are telling us something is wrong, dammit I want to see it corrected.”

Gomez, a retired naval engineer, said harsh ocean elements require extra-sturdy construction and strict procedures. He criticized the apparent lack of thoroughness by the builders and suggested they retrain at welding shops at the Quonset Business Park.

Affigne noted that Weeks was being scrutinized for a second time in two months. “They are at the plate and there are two strikes here,” he said. “Is there a problem in the management relationship between Deepwater Wind and Weeks?”

Theodore Hofbauer, a director for ABS, said he needed to investigate the matter before he could answer.

Deepwater Wind president Chris Van Beek said he communicates regularly with Weeks. He stood behind the flawless test results for the welds. The welders, he said, are certified to work or have worked extensively in offshore construction. He promised to provide any missing documentation. Any faulty welds would be fixed quickly, he said.

“So far, the welds have been tested and they are 100 percent correct,” Van Beek said. “I don’t think there is any trouble with the welds.”

By TIM FAULKNER/ecoRI News staff

PROVIDENCE — Construction of the Block Island Wind Farm is once again raising red flags and upsetting state officials. Last month, the Deepwater Wind project caused alarm after inspectors found equipment damage and a number of hazards that threatened worker safety.This month, attention shifted to the quality of construction — specifically welding procedures and construction practices by the builder, Weeks Marine of Cranford, N.J.

The list of problems includes broken testing equipment, unused moisture-extraction ovens and a lack of documentation. The problems were reported by ABS Group, a consultant hired by Deepwater Wind to monitor construction of the five-turbine wind farm.

“Every one of those issues to me is a major issue,” said Donald Gomez during the Sept 22 meeting of the Coastal Resources Management Council (CRMC), the state agency overseeing most aspects of the project. “You don’t work that way.”

Other CRMC members described the irregular practices as “very concerning.” Several were agitated by the prospect of unverified welding, unused and broken welding equipment, and faulty quality-control devices.

Some welding isn’t being documented nor is it sanded properly, according to Houston-based ABS. However, final inspections of the welds performed by Weeks awarded flawless scores. The grading was referred to as “implausibly 100 percent perfect” by CRMC council member Tony Affigne.

CRMC vice chairman Paul Lemont demanded better oversight from ABS.

“We don’t want to be caught short-handed here, because we’re on the hook and if something goes wrong they (the public) are going to look to us, and if you are telling us something is wrong, dammit I want to see it corrected.”

Gomez, a retired naval engineer, said harsh ocean elements require extra-sturdy construction and strict procedures. He criticized the apparent lack of thoroughness by the builders and suggested they retrain at welding shops at the Quonset Business Park.

Affigne noted that Weeks was being scrutinized for a second time in two months. “They are at the plate and there are two strikes here,” he said. “Is there a problem in the management relationship between Deepwater Wind and Weeks?”

Theodore Hofbauer, a director for ABS, said he needed to investigate the matter before he could answer.

Deepwater Wind president Chris Van Beek said he communicates regularly with Weeks. He stood behind the flawless test results for the welds. The welders, he said, are certified to work or have worked extensively in offshore construction. He promised to provide any missing documentation. Any faulty welds would be fixed quickly, he said.

“So far, the welds have been tested and they are 100 percent correct,” Van Beek said. “I don’t think there is any trouble with the welds.”

Missing information

ABS is also charged with overseeing construction of the components used to assemble the 6-megawatt wind turbines. Turbine manufacture Alstom, however, has been slow to provide information for ABS to review. Partial information has been received for some components. ABS missed the production for the main bearings and the pitch system, two components that the CRMC has expressed an interest in monitoring.

“We’ve been asking for information and haven’t received it from Alstom for some time now,” said Rain Byars, project manager for ABS.

Byars said Alstom didn’t have a quality manager for several months, which likely caused the slowdown in receiving information.

“Unfortunately, this has been an ongoing issue with Alstom,” Byars said.

Van Beek blamed the size and complexity of a multinational corporation such as Alstom and a language barrier — the company is based near Paris — for the delay in receiving information about component construction.

Gomez again expressed concern over faulty calibrators and unused equipment at the Deepwater site. “I still think that a process needs to be followed and the equipment needs to be right,” he said.

“We’re not saying it’s right or wrong,” Hofbauer said. “We’re saying we don’t have enough information at this point to say it’s right or wrong.”

Affigne said the contentious meeting was a healthy process for vetting information. “If every meeting is like this, then I think we are going to be in good shape,” he said.

Safety issues

ABS also gave an update on several safety concerns raised during the August CRMC meeting. The issues at the wind farm site, some 3 miles off Block Island, included dropped objects, loss of control of suspended loads, employees working under suspended loads, and other onsite hazards.

ABS reported that Weeks has since made several safety improvements. Training has increased.

Safety representatives are on all vessels. Protective bumpers have been added to barges.

In order to create a steadier work platform, the jack-up lift boat Roberts is making its way to the site. The barge-like boat has an attached crane and legs that anchor into the sea floor to provide stability.

The damaged foundation sleeve that was hit by a barge in late July has been repaired and returned from New Jersey.

A lack of lighting on the cranes, however, is a new problem. During night construction, the booms from two cranes have come into contact. Handheld lights are illuminating the second boom until light fixtures are installed. Damage also is being assessed after a crane ball struck the crane boom.

“From a safety standpoint, we’re very pleased with the direction things have turned,” Hofbauer said. “There’s definitely been a much different attitude and view toward safety going forward and we are very pleased with that.”

ABS is also charged with overseeing construction of the components used to assemble the 6-megawatt wind turbines. Turbine manufacture Alstom, however, has been slow to provide information for ABS to review. Partial information has been received for some components. ABS missed the production for the main bearings and the pitch system, two components that the CRMC has expressed an interest in monitoring.

“We’ve been asking for information and haven’t received it from Alstom for some time now,” said Rain Byars, project manager for ABS.

Byars said Alstom didn’t have a quality manager for several months, which likely caused the slowdown in receiving information.

“Unfortunately, this has been an ongoing issue with Alstom,” Byars said.

Van Beek blamed the size and complexity of a multinational corporation such as Alstom and a language barrier — the company is based near Paris — for the delay in receiving information about component construction.

Gomez again expressed concern over faulty calibrators and unused equipment at the Deepwater site. “I still think that a process needs to be followed and the equipment needs to be right,” he said.

“We’re not saying it’s right or wrong,” Hofbauer said. “We’re saying we don’t have enough information at this point to say it’s right or wrong.”

Affigne said the contentious meeting was a healthy process for vetting information. “If every meeting is like this, then I think we are going to be in good shape,” he said.

Safety issues

ABS also gave an update on several safety concerns raised during the August CRMC meeting. The issues at the wind farm site, some 3 miles off Block Island, included dropped objects, loss of control of suspended loads, employees working under suspended loads, and other onsite hazards.

ABS reported that Weeks has since made several safety improvements. Training has increased.

Safety representatives are on all vessels. Protective bumpers have been added to barges.

In order to create a steadier work platform, the jack-up lift boat Roberts is making its way to the site. The barge-like boat has an attached crane and legs that anchor into the sea floor to provide stability.

The damaged foundation sleeve that was hit by a barge in late July has been repaired and returned from New Jersey.

A lack of lighting on the cranes, however, is a new problem. During night construction, the booms from two cranes have come into contact. Handheld lights are illuminating the second boom until light fixtures are installed. Damage also is being assessed after a crane ball struck the crane boom.

“From a safety standpoint, we’re very pleased with the direction things have turned,” Hofbauer said. “There’s definitely been a much different attitude and view toward safety going forward and we are very pleased with that.”